Norfolk County tobacco in its prime.

Gardening is a passion for many. It’s also an education. Living in the suburbs today, I now realize my first summer jobs in tobacco were an education on a grand scale.

But when you are sweating it out along a sandy trail between endless rows of voluptuous green, you don’t recognize the perspective it gives to one’s view of the world from then on.

Let me tell you about growing this insidious, but historic, magnificent plant.

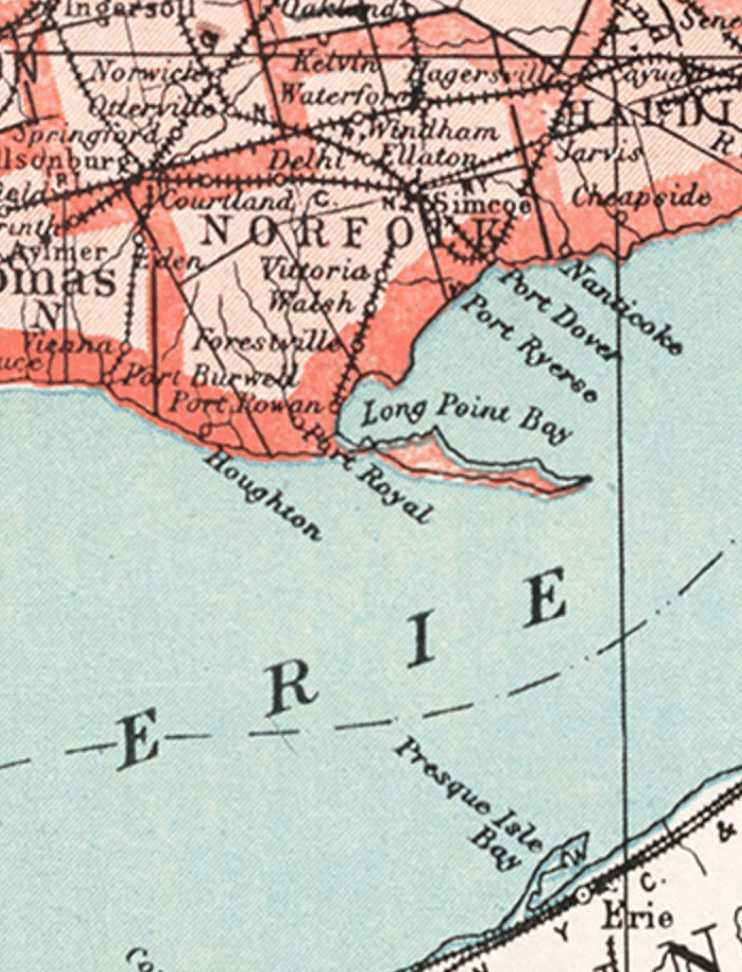

Norfolk County is a sandy-loam, verdant garden on the north shore of Lake Erie. It’s recognizable on any map by the 22-mile spit of sandbar called Long Point that hooks into the center of the lake. Flying from Chicago to Toronto, you can see the milky currents wrapping around it from the air.

Today tobacco is a small fraction of the agriculture in Norfolk, but from the 1920’s up to the ’70s, tobacco farms neatly patched the landscape, rich in wealth and long in work.

The Norfolk growers are proud of their neat and efficient farms.

A 100 acre tobacco farm could furnish a family nicely, provide for a new car every few years, fund college, build barns and also buy a trip off to Florida for a well earned vacation in the winter. It would take a 1,000 acre wheat farm to deliver the same income.

But making that all come together required interminably long work, accented by brilliant sun on hot sandy fields.

In March the greenhouses are steamed to heat and humidify the rich soil for germinating seeds.

By May, millions of shoots are ready for transplanting.

In late March the growers steam the greenhouses, getting them warm and moist to germinate microscopic tobacco seeds which are sprinkled across rich, black dirt like poppy seeds. These grow to 12-inch shoots by May, ready to be pulled and planted.

The shoots are planted from behind a tractor. Two workers, usually women, sit on a frame and feed plants into a steel wheel that parts the sandy soil into a furrow, drops the tobacco plant, and then closes the furrow behind.

You can plant more than 10,000 shoots in one acre.

Early June and school’s out, and summer jobs begin to blossom, just as the adolescent tobacco plants are spreading their first leaves, called “sand leaves”. All manner of weeds try to overtake the tobacco. Our first serious job is to scrape a hoe between each plant, spaced roughly 18 inches apart.

Hoeing: meticulous painstaking work.

It’s 7 in the morning, and we are at the edge of the field. Mourning doves are cooing, off in the bordering woods, and the air is fresh with the scent of dew evaporating on the tobacco.

Hoeing is a walking activity. Wearing a hat, shirtless, and in shorts, I shuffle along a row carefully carving out weeds between the tobacco. There’s a million plants, shared by five workers: me and 4 women.

It’s painstaking work. If careless, the hoe will cut the tobacco plant, which will cost the grower money, and that can be painful.

Most memorable along these interminable rows was the unceasing chatter among the workers, sharing stories from family fortune to family scandal. As the youngest in the group, and as the only male, my role was to listen, and take the jibes from the women.

Do-over: the replanter dropped a new plant and a cup of water into the soil.

Then there’s replanting for dead and missing plants. Toting a six-quart basket with new plants and a water tank strapped to my shoulder, a replanter punches a hole in the furrow, drops a plant down the chute, pulls a lever on the chute and a cup of water is dispensed.

Replanting is my punishment for hoeing a plant under, a week ago.

My recollection of this job is twofold: the rows are unending, and the cold water from the farm’s well, pumped by a windmill, is heavily laced with sulphur. After 10 in the morning, the sun is high. The body dries up pretty quickly, and water breaks were serious and necessary. Gulping down a pint of icy sulphur water is a challenge.

By 3 in the afternoon, staring along the next row, the heat waves make the woodlot at the other end a shimmering green plasma. No matter; we work until 4:30 or so. After a few days of hoeing, the frigid sulphur water tastes sweet.

Long straight lines at 2 miles per hour.

Next, we cultivate. The tractor pulls a wheeled, steel frame manned with two guys, heads down, hands controlling little rakes, zigging and zagging between each plant, digging out a second round of weeds. Great for building your pecs and ceps.

I drive the tractor. This is hot work, roasting slowly over a 6-cylinder diesel Massey Ferguson. So hot and monotonous that I fall asleep behind the wheel. I have driven across three rows before I wake to the scowls and groans of the boss’s sons who are zig zagging behind me.

Stone age cultivator, left by the Tuscarora.

The upside of walking or driving down countless rows is finding a handful of ancient arrow heads and prehistoric farm tools along the way, remnants from the Tuscarora that long since have moved on.

Every day the tobacco continues to sprout new leaves as it shoots skyward.

The flowers are lopped off to encourage leaf growth.

When the plants have mushroomed to shoulder high, we take a brisk walk down the rows topping off the flowers to encourage a fuller plant.

August brings heat and showers, and cooler nights. The tobacco plant has about twenty broad leaves, stands a good 5-6 feet high, 3 feet across, and is rich green and aromatic. The leaves are as large as tennis rackets, and along the stems, they sweat beads of juice which turns to black tar on the hands after a while.

The harvest begins. On my first tobacco summer, 1965, we had 5 “primers”…pickers from South Carolina. They walked the rows, hunched over, pulling leaves, starting with the sand leaves. They earned this name as their bottom sides are coated with sand. It’s seven-days-a-week work, because the crop is an unstoppable force, growing as fast as it can.

Priming: picking the leaves is back breaking work. Nowadays primers ride picking machines.

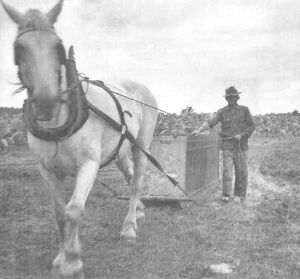

The primers pull off the leaves, usually about three per plant, and tuck them under their arm until they have a bundle of 30-40 bunched up like stacks of green newspaper. Standing up, they bring the leaves over to a horse-drawn tobacco “boat” that follows in the row.

The boat was on wooden runners, and pulled by a tired horse who probably wondered daily how he ended up here sweating in the field. The primers were sympathetic, but not kind, and pretty course with their language for the old gentleman who didn’t need the work.

My first job was on a farm with horse drawn tobacco boats.

The priming crew will go through the hundreds of rows of tobacco 3 or 4 times to pick all the leaves as they mature.

When the boat is full, at the end of a row, it’s winched onto a trailer and tractored back to the tobacco kiln. In Norfolk, we called them “kills”.

The tobacco kilns were a landmark of Norfolk County.

A typical tobacco kiln stands about 20 feet high, and 25 feet square. Usually covered in green tar paper with red doors, these cube-like structures dot the landscape. Every farm has at least 7 kilns, one for every day of curing required.

Hand tying: a lost art. Each stick carried about 10 pounds of leaves.

But before the tobacco is placed in the kiln, the leaves are sewn onto sticks, each about 4 feet long.

It used to be that tobacco was hand-tied onto the stick. About three tobacco leaves were half-hitched at a time by their stems, by a lady using a continuous string. A good tier could tie about 10 pounds of leaves onto a stick in about a minute.

The tobacco tying machine delivered speed and finished product faster.

Sometime in the 60s, someone invented the more contemporary tying machine. This is a conveyor belt with an industrial stitcher.

Three ladies run the machine. The first pulls a bed of 20 leaves, by their stems, onto the belt, and as the belt moves along, she grabs another set of leaves for the next bundle. Lady #2 would lay down some more leaves, plus a tobacco stick, and pulls some more leaves on to cover the stick. Lady #3 continues laying on leaves as the stick goes by, under a roller, and under the stitcher. It delivers 10 pounds of leaves straddling the stick. All to the rise and fall of a conversation that flows with the chatter of the stitching machine.

The ladies turn out 2-3 sticks a minute.

The kiln hanger strung up 2-3 sticks per minute, skipping across 20-foot-high beams.

These leafy sandwiches are sent up a second conveyor into the kiln. The kiln hanger, who is me, waits at the other end, standing on a shaky row of 2 x 10 boards, loosely resting between two beams, 15 feet above the dirt floor. I grab the stick by its middle, and suspend it in notches between two beams over my head.

There’s enough time to walk on the boards to the notches, place the stick, and get back for the next stick.

Occasionally I miss a notch, or a stick breaks, and it plummets to the ground, crashing on the beams below and landing in a pile of leaves like a great wounded bird, with green feathers everywhere.

When a row is finished, I move the 2 by 10s to another position, either below or above me, and climb into position. The conveyor is moved, raised or lowered. The conveyor jumps into motion. One wrong step and I join the bird.

At the end of the day, all of the doors of the kiln have been closed snugly over the bulging sticks of tobacco. 1200 sticks, 6 tons of tobacco, wet.

A typical kiln holds 1200 sticks. We filled 40 kilns during harvest.

Harvest takes about 5 weeks, finishing after Labor Day, unless we get frost early.

Standing in the doorway of the kiln and looking up, I see a mouse’s eye-view of a beautifully trimmed forest of leaves, in hundreds of orderly rows, hung like romaine lettuce, ready for baking. Early in the harvest, those leaves drop millions of grains of sand, so an upward look usually ends up with watery eyes.

Kiln fires gave a frightening glow across the sky at night.

In the early days of tobacco curing, hot open flame oil burners were lit below the leaves. This is flue-curing. A harvest never went by without a dozen kilns going up in smoke and flames, a spectacular, punishing and frightening sight, all at the same time.

During the 60s someone got the idea to have forced air blown through an external furnace, and into the kiln, removing the threat of fire. A local entrepreneur made a fortune manufacturing the blowers for all the kilns in Norfolk.

The tobacco is flue-cured in the kiln for about 7 days. Warm, dry air is circulated bottom to top among the leaves. By day seven, it is golden and smells sweet and peppery. Each leaf has given up a cup of water, and has shrunk to the dimension of a tired dish towel.

In the late 70s tobacco pickers rode a machine with baskets. No more stoop work, no more horses.

Late after supper on the 7th day, or early in the cool dark morning of the 8th day, a crew brings a wagon up to the kiln, and gingerly unloads the kiln. They gently lay the sticks of tobacco down on the wagon bed, being careful not to damage the leaves. The kiln is ready for a new batch.

I have personally touched, hung, or cultivated every one of the leaves in this kiln. By summer’s end, I have loaded 40 kilns.

The harvest is pulled to the tobacco barn where it will remain until stripping, sometime in November. The sticks and tobacco string are stripped from the leaves which are then bound into bales the size of a kitchen microwave.

I never saw the stripping process, but reportedly, it occurs in a hot, humid room which forces the strippers to shuck off their clothes after a while. The event is aptly named, and there are tales of racy, raunchy humor surrounding it.

The auction house in winter. The product was bought, and exported to the far east.

Hometown Delhi, center of the Canadian tobacco industry.

Sometime in January, the growers take their bales to auction, and there they are sold to cigarette manufacturers like Imperial Tobacco, Rothman’s and MacDonald Stewart, whose Canadian customers prefer the Ontario flue-cured leaf, much different than the tobacco that comes from the southern states. Today, that market has been dwarfed by the far east, where smoking is more popular, and less regulated.

The “dutch auction” is an unusual process. A ceiling price is first established, and then the single hand of a clock spins slowly through descending prices. The first buyer to hit their buy button wins the grower’s lot.

From the auction house the grower’s tobacco is trucked to the factory. In my hometown of Delhi, the Imperial plant was on the south side.

Another planting. The young crop absorbs sun and rain before its explosive growth.

By early February and March the plant was processing tobacco, and when a warm south wind blew across town, there was a pervasive, mildly exciting, sweet earthy fragrance that tickled the nose. Unforgettable, 50 years later.

As I said at the outset, tobacco is a magnificent plant, and troubling too. I have no use for it, and can’t recommend it. Still, a good crop is a work of discipline, and there isn’t a day that those priceless memories of demanding, careful labor, delivering a harvest–a real summer job–don’t come to visit.

And I like to garden, too.

Thanks for reading! This was as long as some of those rows. It’s been years since my days in Norfolk. I can’t forget the smell and feel of the countryside. It’s sweet and distant, and I always like to go back to visit. Who says you can’t go home again?